The most widely used crystal label printer in the market, Guangzhou Kangyin Digital Crystal Label UV printer, has the advantages of fast speed, strong stability, and the integration of material receiving and discharging, and film covering. The entire machine can be equipped with 3 nozzles, and the printed product pattern is bright and full, with a 3D pattern effect of tearing film and leaving patterns. It also has the characteristics of scratch resistance and high and low temperature resistance. Kangyin crystal label transfer sticker has the advantages of easy adhesion, environmental protection, good texture, waterproof and wear-resistant, bright colors, and wide range of use. Next, let's learn about the steps of crystal label UV printer UV fully automatic printing!

1. Design pattern: Firstly, it is necessary to design a pattern that needs to be transferred to the surface of the product according to the customer's needs. This can be done using computer graphics software or by hand drawing the pattern.

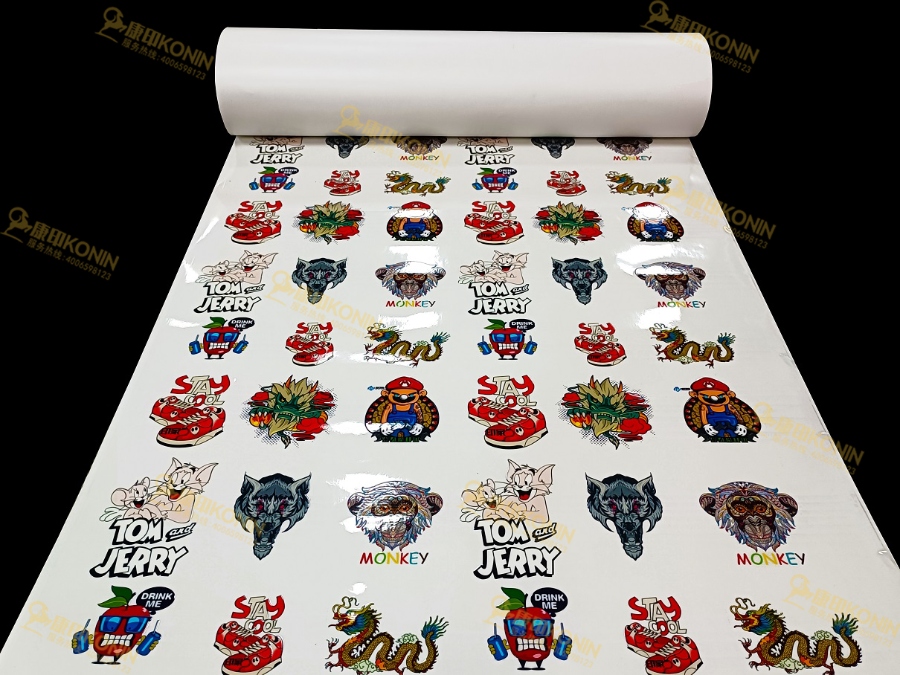

2. Printing patterns: Use a Kangyin crystal label UV printer to CNC print patterns on a computer. Prepare the printed material AB film, where A film is a viscous film and B film is a transfer film. Print the patterns on A film.

3. Film coating: The pattern is printed on the A film, and after printing, both sides are coated with film. This is a crystal label UV printer that integrates receiving, discharging, and film coating. The finished product is the completion of film coating.

4. Cutting: We cut the printed AB film crystal label according to the size of the pattern and have it ready for use (using scissors and a rolling mill for cutting, which is simple, convenient, and fast, and you can also use an automatic edge cutting machine).

5. Transfer printing: Apply the crystal label transfer printing to the surface of the product, remove the back film (i.e. A film) of the crystal label product, hold the B film and apply it to the surface of the product that needs to be pasted with the pattern. Press once to remove the B film, and the pattern is transferred. The entire process is to press and remove the film to leave words.